Yoga Studio/

Invisible Studio

Project Details

Location(City/Country):

Somerset / United Kingdom

Tipology:

Cultural

Year (Design/Construction):

2021 / 2022

Area (Net/Gross):

- / 100 m2

Operational Carbon emissions (B6) kgCO2e/m2/y:

-

Embodied Carbon emissions (A1-A3) kgCO2e/m2:

5- The project takes advantege of natural light through its 11m rooflight, made from a insulated double-glazed unit.

- The Yoga studio uses rammed stone made from local limestone as its external skin. The use of local materials helps to reduce the environmental impact of the project.

- The use of wood, a natural and renewable material, as one of the main building interior materials reduces the building’s carbon emissions.

Project description as provided by the Architects:

A general description of project

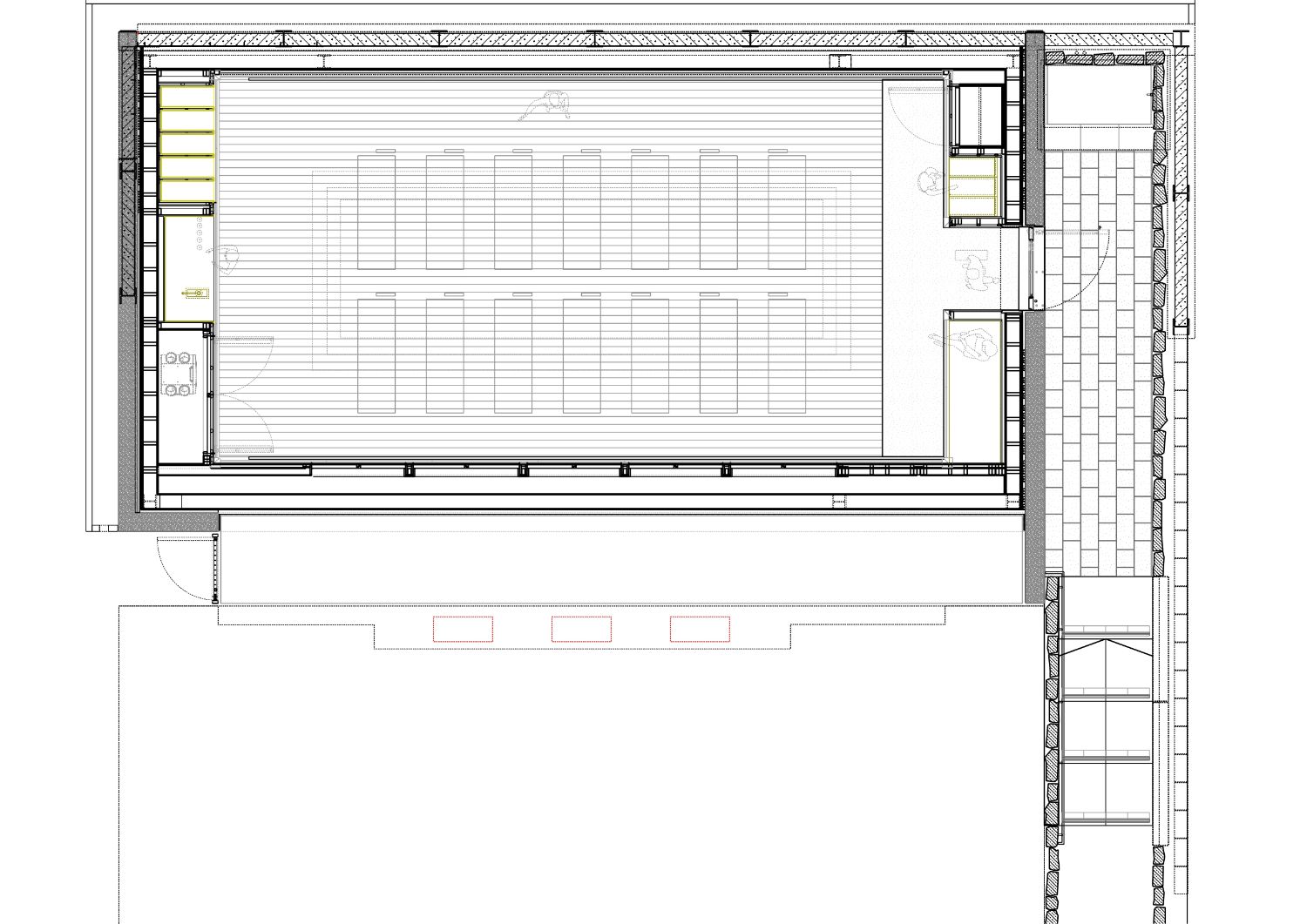

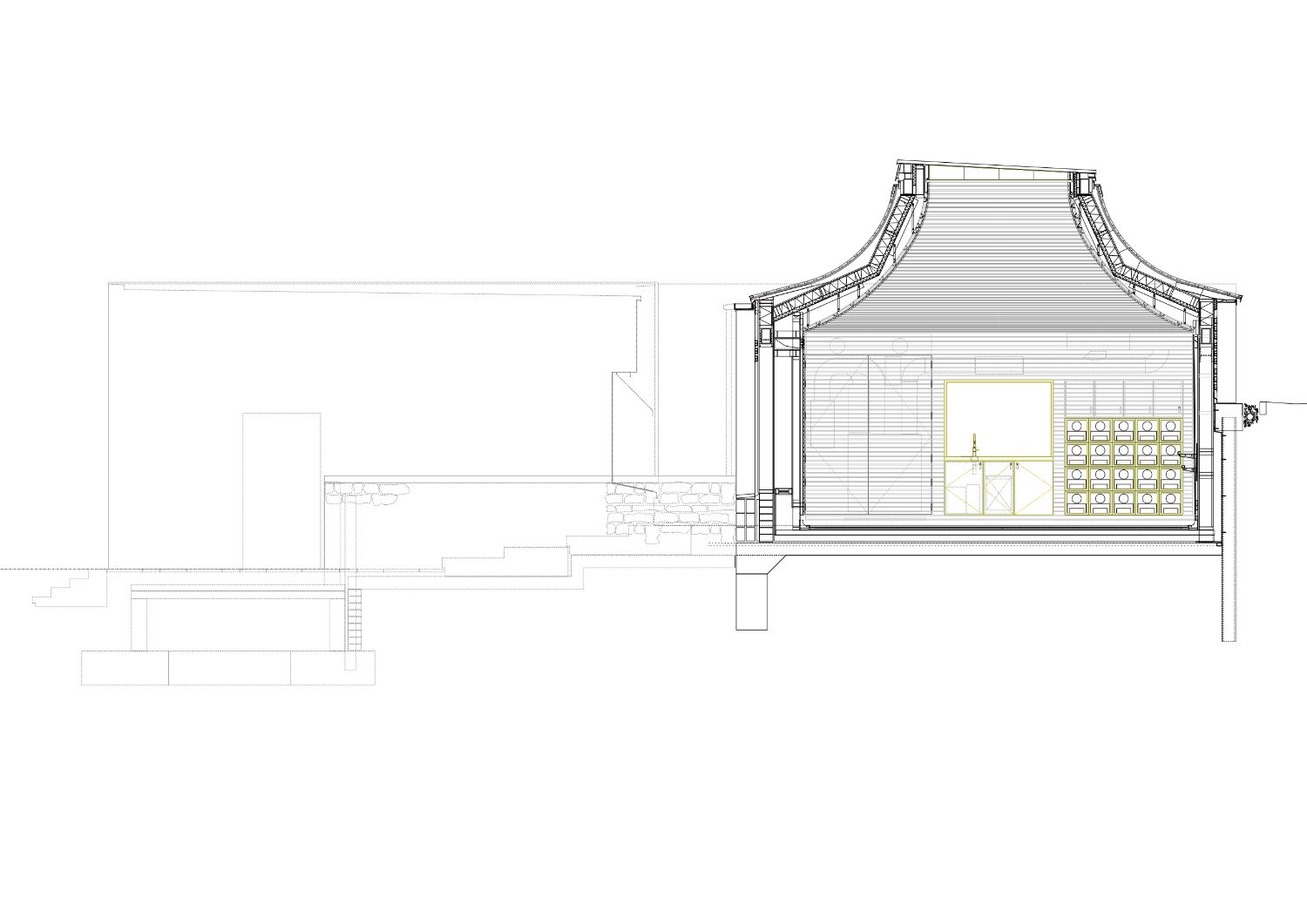

The new Yoga Studio at the Newt Hotel in Somerset is the third building at the Hotel completed by Invisible Studio and is a complementary building to both the Gym (Room in a Productive Garden) (to which it sits adjacent) and the Beezantium. While the Gym had a single view of the vegetable garden via its enormous window, the Yoga Studio has a single view of the sky via its enormous 11m rooflight, made from a single insulated double-glazed unit.

The Yoga Studio at the Newt Hotel is lined entirely in beech slats, providing a warm and immersive sanctuary like space. The need for the yoga studio grew out of carrying out informal and impromptu yoga classes in the Beezantium while the hotel was waiting for the exhibition fit out to be carried out, and the hotel asked for a similar top lit space, but located behind the Gym. The Yoga studio use same rammed stone as the Gym, made from local limestone that gives it its distinctive red colour. The copper detailing also borrows from the family of materials established by the Beezantium.

An architect’s view – describing a key feature / innovative aspect of the project (+ named author)

The rammed stone external skin is something we get asked about a good deal, particularly with no roof overhang. The mix is coloured only by using local ‘Hadspen’ limestone, which has a distinctive red hue, which is crushed from 45mm to dust. There is no sand added – just a small amount of binder which in this case is lime/GGBS/Cement.

We have used the Material Science Lab at the University of Bath for testing numerous mixes, and we have experimented extensively with just using lime, but the curing process means the shuttering has to stay up much longer and it also hard to get the strength required. Pete Walker – an engineer at the University – is a rammed earth expert and has been incredibly helpful. The walls are set out using a 600mm lift, with approx. 4-6 ‘pour’ layers in every lift. The stone was all mixed on site, and poured bucket by bucket into the formwork.

There are stainless steel tubes in the wall to ventilate a cavity behind, which is formed using Surecav. The external skin is tied back through the surecav to a ply sheathing fixed to an internal studwork wall. The roof membrane is dressed over the parapet at the top to protect it, but held back an inch or so from the edge to conceal it. The exposed portion is then protected by a shelter coat.

Piers Taylor

Photo Credits: Jim Stephenson