Tekila House/

Medio Arquitectura

Project Details

Location(City/Country):

Lican Ray / Chile

Tipology:

Residential

Year (Design/Construction):

- / 2022

Area (Net/Gross):

140 m2 / -

Operational Carbon emissions (B6) kgCO2e/m2/y:

-

Embodied Carbon emissions (A1-A3) kgCO2e/m2:

-- The structure is all made of laminated pine. The wood is a natural and renewable material and reduces the environmental impact and carbon emissions.

- The project was designed with efficiency walls, floors and ceilings reducing energy demand.

- The house was designed to let the sun in in the winter to heat the project and keep it out in the summer.

Tekila House is located in the south of Chile, in the Araucanía region, a few kilometers away from Lican Ray. The main requirement was to design an efficient, comfortable, well-lit house with a good view of the lake.

The site is defined by Lake Calafquen to the south and the native forest to the north. The main decision was to raise the project from ground level with two objectives; the first is to face the north, the sun in the southern-hemisphere allowing the greatest entry of light and heat, and the second, is to obtain a better view of the lake.

The terrace projects to the south to contemplate the lake and protect itself from the summer sun. The main space, composed of the dining room, living room, and kitchen, is positioned in an east-west direction, in this way it manages to have a view of the lake and the forest. A double height is projected with a connection to the second floor, facilitating the interaction between the inhabitants.

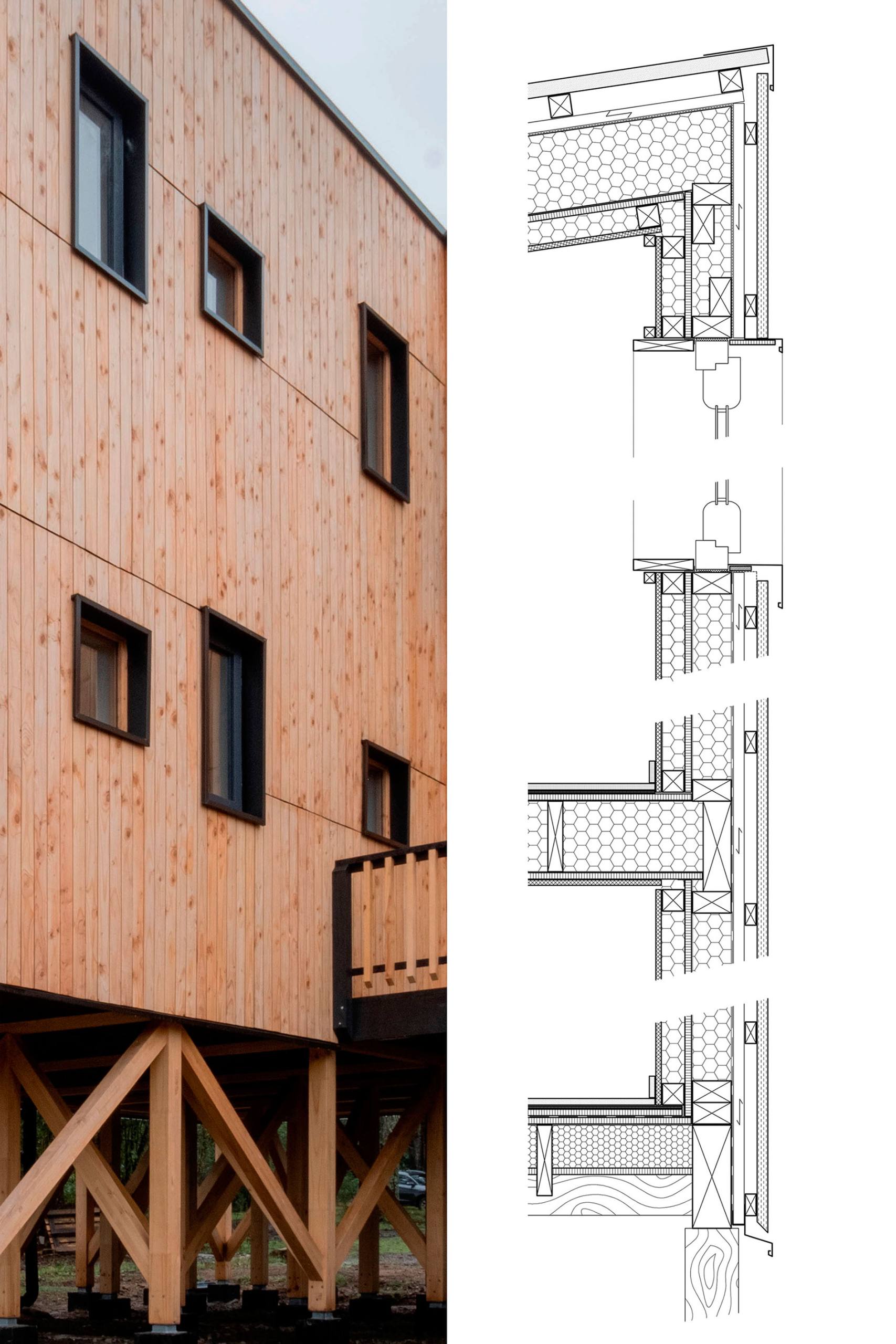

All the structural wood of the project is prefabricated and machined by the local company TIMBER. It was built at its factory in Temuco and was assembled on-site by carpenters from the area in charge of the construction company VIPROC. The structural base of laminated wood was designed with thin and light elements that seek to integrate into the context. The façade was prefabricated on the ground, separating it into different parts, which were assembled by the carpenters on site. 1×4″ Oregon boards were used, separated 1 cm each and with a 45-degree cut at their ends, to avoid water stagnation. Exposed screws were avoided throughout the façade to protect the wood and thus be able to appreciate it in its entirety.

We always choose wood as the main design material, as it is a versatile, sustainable, and thermally efficient material. In this project, advanced wood technology was used, such as mechanized and prefabricated laminated wood, and at the same time the traditional carpentry of the area. The same carpenters are in charge of assembling the entire prefabricated structure and working in a traditional way on the facades and interior finishes. We believe it is relevant and necessary to continue advancing in the development of both new technologies and traditional carpentry knowledge, since both complement and enhance each other, achieving very good results.

Photographs: Emiliano Ruidíaz Riffo