Rigot Collective Dwelling Centre/

Acau architecture sa

Project Details

Location(City/Country):

Geneva / Switzerland

Tipology:

Residential

Year (Design/Construction):

2017 / 2019

Area (Net/Gross):

- / 7.070 m2

Operational Carbon emissions (B6) kgCO2e/m2/y:

-

Embodied Carbon emissions (A1-A3) kgCO2e/m2:

-- An optimised and flexible design allows for the buildings prefabricated units to be relocated in the future.

- Prefabrication reduces the volume of raw materials involved.

- Structural elements made of wood, CLT and GLC.

- Foundations are made of wooden piles and footings.

- The wood used was locally sourced from Geneva’s forests.

- The project execution integrates recycling principles at all scales.

Project description as provided by the architects.

The Rigot Collective Dwelling Centre is located in the Rigot park in Geneva, alongside the Avenue de France, near the Sismondi school. The choice for the location in the park was impulsed by an urgent and temporary measure aiming at accommodating 370 migrants.

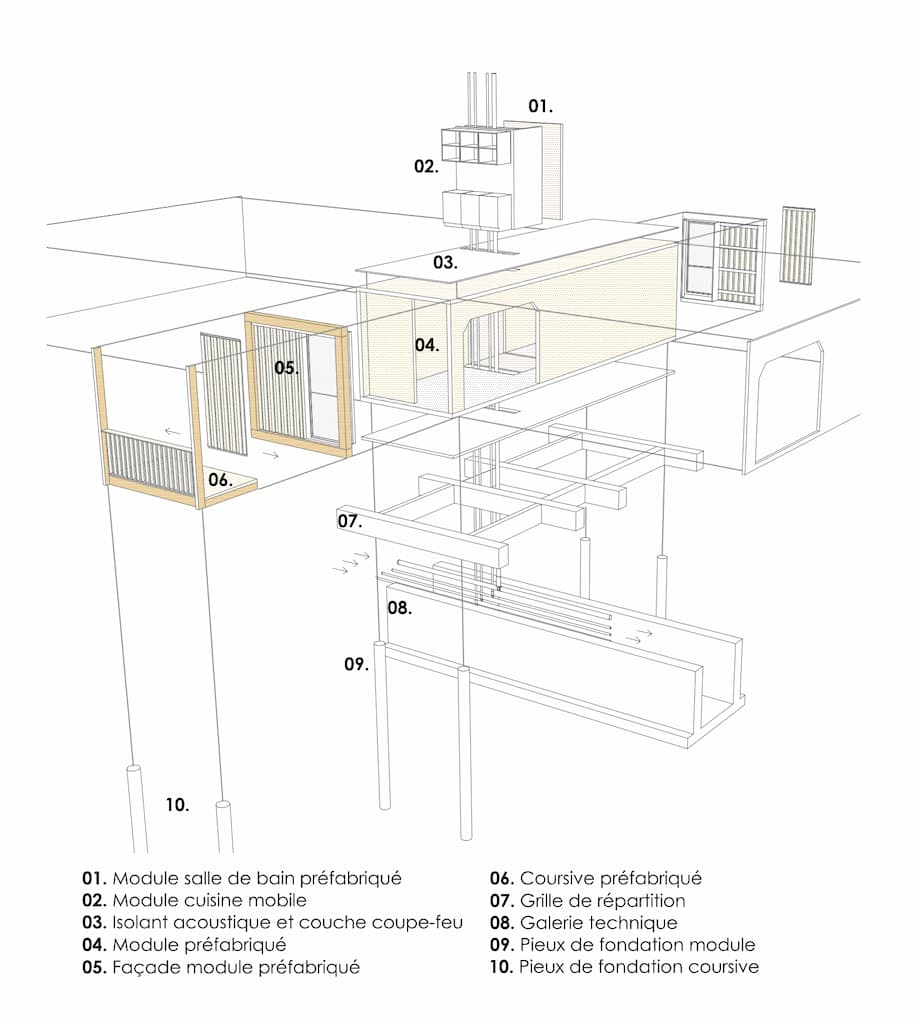

The project consists in two symmetrical buildings of 5 levels made of 230 prefabricated wooden modules. The dwellings are accessed by an external gallery open to a public courtyard, which connects to the Sismondi streetcar stop to the Rigot park.

ENVIRONNEMENT

Through its constructive mode, the Rigot Collective Dwelling Centre aims to limit its environmental impact at various scales such as:

SITE SCALE:

The buildings are bound to be relocated within ten years and the site returned to its original state. Anticipating the rehabilitation of the site and the recycling of the materials upon removal, the foundations are made of wood and can be reused on the next building location. The crafting of the foundation through a network of piles and wooden footings reduces the project impact on its natural ground. This totally “dry” construction avoids any contamination of the surface water network during construction and frees the process of the burden of recycling concrete in the dismantling phase of the project.

REGIONAL SCALE:

The project taps on local forestry; the materials require little “grey energy”. The optimisation of the product offered by prefabrication reduce the volume of raw materials involved.

SOCIAL

Through the very essence of its refugee sheltering program, the Rigot Collective Dwelling Centre provides an answer to the current social challenges.

GLOBAL SCALE:

The project responds by housing the displaced through forced migration of vulnerable populations.

LOCAL SCALE:

The aim of the Hospice Générale and the Conseil d’Etat to design an exemplary project reinforces its creed of facilitating integration through quality housing. The character of the building, determinated by the use of natural wood, conveys a positive image to which the residents can identify.

PERSON SCALE:

The project anticipates the specificity of a population who is not always the mirror of the typical couple with two kids.

To respond the waxing and waning of the demand, the project proposes evolving apartments typologies. The modular system allows the housing units to vary from 2 to 8 rooms through a play of fires doors or conversion of kitchen spaces to bedroom.

The modularity of the apartments and their subdivisions also allows to consider alternatives uses such as hotels industry or student housing. The set of composition of the prefabricated modules will enable the creation of buildings with different volumetry for its future(s) reconstruction(s).

ECONOMY

The prefabrication and delivery of the finished modules was decisive for the construction site planning. This organization which plans three worksites in parallel (foundations / prefabrication of modules / assembly and finishing) allows the project to be carried out in a short period of time.

The use of wood from Geneva’s forests for the foundations and the building envelope was imposed since the start of the project, which led to a process that involved the local timber manufactures, resulting in reduction of “grey energy”.

The quantity of wood that was used for the project is estimated at 3200 m³ of certified “Label Bois Suisse” wood (formerly COBS), with the exception of the larch window frames that consolidate the façade.

RECYCLING AS THE ESSENCE OF THE PROJECT

Based on the positive assumption that refugees housing should be temporary, the Rigot Collective Dwelling Centre execution integrates recycling principles at all scales.

The modularity of the apartments and their subdivisions, which meets the acoustic and fire safety regulations, allows to consider alternatives uses such as hotels industry or student housing.

The set of composition of the prefabricated modules will allow, for its future(s) reconstruction(s), the creation of buildings of different volumetry. Once dismantled, the prefabricated modules are reusable on sites that do not provide the same ground surface as Rigot. It’s likely that in the long run, the resource offered by these 230 modules which compose the project will be used to craft projects with different volumes and vocation.

STATIC AND STRUCTURAL PRINCIPALS

Built on wooden foundations and without rigid vertical core, the building’s static is ensured by two main principles:

A recovery of vertical loads guaranteed by the superposition of the GLC walls of the modules.

A recovery of the horizontal forces guaranteed by the assembly of rigid solid larch frames on the facades.

The robustness of the modules, composed of GLC panels, contributes to fire resistance and guarantees a high efficiency during disassembly and reassembly. The assembly of the modules is done by bolted pins which excludes any intervention altering the interior or exterior finishes work during disassembly.

The prefabrication and delivery of the finished modules is decisive for the construction site planning. This organization which plans three worksites in parallel (foundations / prefabrication of modules / assembly and finishing) allows the project to be carried out in a short period of time. The search of a character which expresses the wooden structure makes a statement about rational aesthetic as the essence of the project.

By the term of the project, we realized that the most critical aspect of the construction is more determined by the production of the modules than by their assembly. The time required to lay the foundations, in a humid soil with challenging weather conditions, weighs on the overall construction schedule.

MODENATURE AND MATERIALITY

Since the beginning of the project, a partnership with Geneva’s foresters and sawyers was initiated. An available supply of oak slabs was proposed by the forester and a calibration of the construction elements that minimizes waste was determined with the sawyer.

The search of a character which expresses the wooden structure makes a statement about rational aesthetic as the essence of the project. Starting from the supply of a single dimension of raw sawn boards, the composition of the façade and the execution of a part of the exterior installations are based on this positive constraint. For the façade, the construction element is declined in two details for the railings and cladding.

PROJECT ACTORS AND OTHER INFORMATION

Name of the project: Rigot collective dwelling centre – Hospice général

Lieu Av. De France 36, 38 PRO, Petit-Saconnex, 1202 Geneva

Client: Hospice général – Service immobilier, 1227 Les Acacias

Project architect: acau architecture sa, 1227 Carouge- Geneva

Construction management: Entreprise Générale SA, JPF Construction SA, 1630 Bulle

Execution architect: Pasquier Glasson sa, Bulle

Civil engineer: T-ingéniérie, Geneva

Civil execution engineer: Thomas Jundt SA, Geneva

Conception incendie: Bois Initial SA, 1110 Morges

Fire safety engineer: Charpente Concept SA, 1258 Perly-Certoux

Wood execution engineer: JPF-DUCRET SA, 1400 Yverdon-les-Bains

Framework companies: JPF-Ducret (VD, FR), Dasta (GE), Casaï (GE)

Sawmill companies: Epicéa : Despond SA Bulle (FR) et Zahnd SA Rueyres (VD)

Chêne : Burgat Saint Aubin (NE) et Corbat (JU)

Wood Label: COBS (parois des modules, plafonds et ossatures, ainsi que pour le chêne des revêtements

de façade et coursives)

Photographers: Enric Rovira, Marcel Kultscher