Technical: Embodied carbon values of common insulation materials

News Detail

Year:

2022

Country:

Global

Source:

Canadian ArchitectLike many architects, we have begun to pay much closer attention to the embodied carbon associated with the materials we are specifying. All other things being equal, selecting a material with a lower global warming potential (GWP) is preferable. However, at this early stage, not many of us have a strong intuitive sense of how meaningful various GWP values might be. For instance, is 223 kgCO2e/m2 of insulation good or bad?

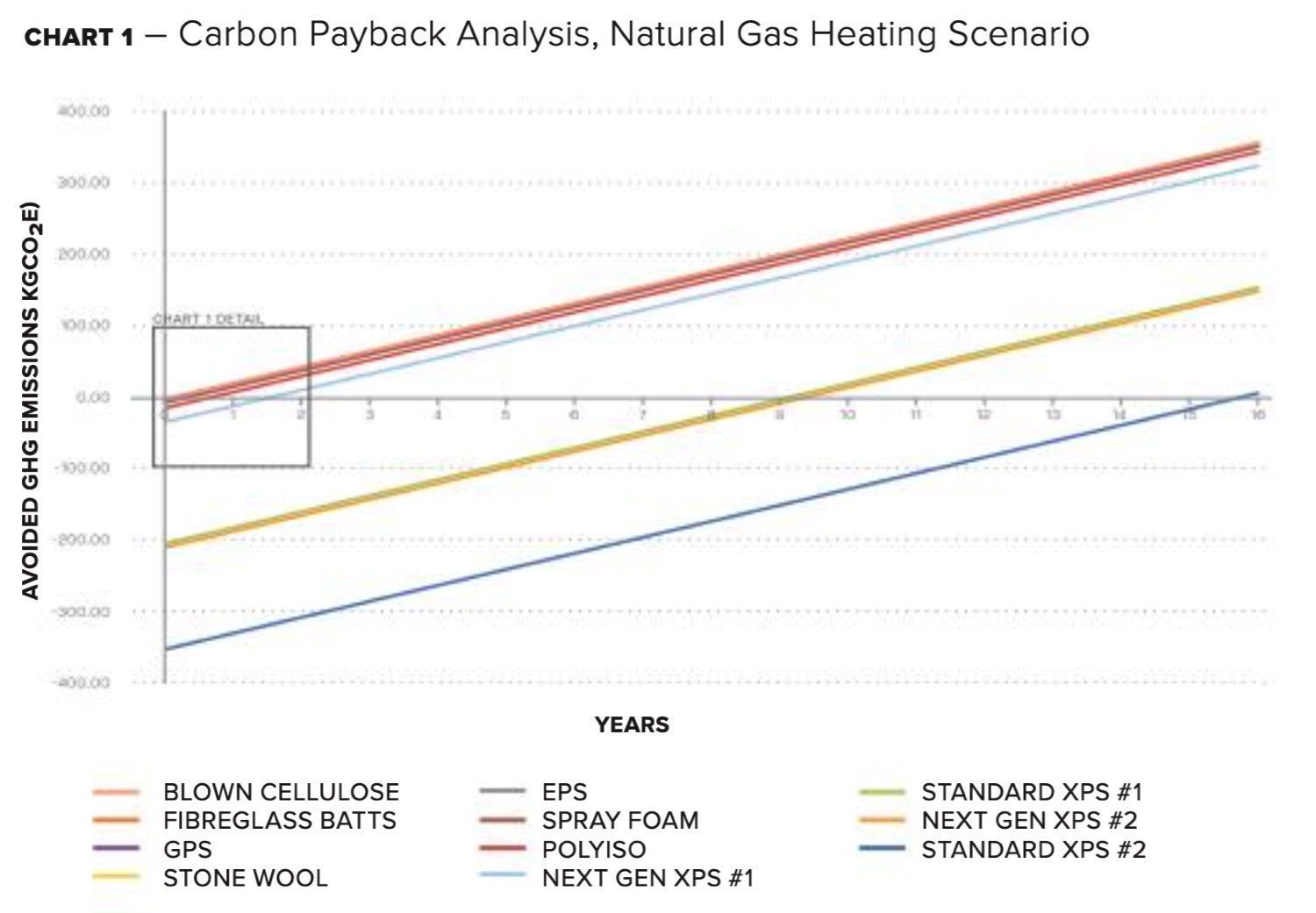

To present GWP values in a relatable way, we performed a study to compare the embodied carbon values for 11 commonly used types of insulation. The insulation products considered include two brands of standard XPS, two brands of next-generation XPS, polyiso, spray foam, EPS, stone wool, GPS, fibreglass batts, and blown cellulose.

Insulation is somewhat unique among building materials in that one of the primary reasons it is incorporated in buildings—to reduce energy flow through the building envelope—directly impacts the building’s operational emissions.

In our study, we contrive a familiar scenario: a homeowner with an uninsulated bearing masonry house wishes to add insulation to reduce their energy costs and increase comfort in the home. Specifically, they would like to increase the effective R-value of their home from its current performance of R4IMP to a value more in line with the current building code, R24IMP.

We calculate the embodied carbon associated with the amount of each type of insulation required to achieve that level of thermal resistance. We then calculate the quantity of emissions that is avoided each year the house is operated with the higher level of insulation (due to the reduction in heating energy needed to maintain the internal temperature of the house).

The conclusion of our study is a payback analysis that expresses the relationship between the emissions associated with the production of each insulation and the emissions avoided each year due to the presence of the insulation. Said another way, we identify how long it takes for the operational savings (reduced operational emissions) to exceed the investment (embodied carbon) in the insulation.

More info