Maximizing the carbon storage potential of wood

The European construction sector is responsible for a significant share of climate impacts of European economic activities, largely through its reliance on carbon-intensive materials such as concrete and steel. With global floor area expected to double by 2060, a systemic shift toward renewable, low-carbon materials is required. Wood, a biogenic resource that naturally sequesters carbon, can transform the built environment into a long-term carbon store. However, the climate potential of wood is currently underutilized due to short-lived applications and limited cascading practices.

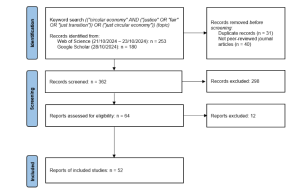

This study, led by Metabolic Institute in collaboration with Stichting Probos, and funded by Built by Nature, applied a material flow analysis (MFA) across EU27+UK wood value chains to assess wood use, carbon storage, and opportunities for wood cascading. The analysis revealed that 560 million m³ of wood enter European value chains annually, equivalent to 516 million tonnes CO₂-eq of embodied carbon. Yet, only 8% of this wood (46 million m³, or 40 Mt CO₂-eq) is used for applications ensuring long-term carbon storage (>35 years), such as structural timber in buildings. By contrast, 31% (172 million m³) is used for short-term uses such as pulping and bioenergy, and another 20% (111 million m³) is lost as processing residues. Together, these streams represent 319 Mt CO₂-eq of annual biogenic carbon emissions.

Secondary processing is somewhat more efficient. Still, 23% of outputs (29 million m³) end up in short-lived secondary products such as packaging components, while 36% (45 million m³) contribute to medium-term carbon storage (10–35 years). This imbalance shows that most of Europe’s wood is not valorized in ways that ensure durable carbon retention.

The report also examined demolition and renovation flows, which release 11.4 Mt CO₂-eq annually (12 million m³). Currently, 62% is incinerated, 27% downcycled, and only a minor fraction reused in applications with a long life span. Given that the total carbon stock already embodied in buildings amounts to 1,193 Mt CO₂-eq (1,253 million m³), the continuation of these disposal practices risks to waste a vast asset for lowering greenhouse gas emissions.

To reverse these dynamics, five industry strategies aimed at maximizing wood-based carbon storage through the application of cascading principles and circularity in the use of wood were developed and modeled for moderate and ambitious implementation scenarios:

1. Redirecting short-lived uses to applications with a long life span, prioritizing high-quality uses of wood in the construction sector, could yield up to 90 Mt CO₂-eq stored by 2050 (+84% over business as usual).

2. Improving resource efficiency in products and processing can deliver up to 160 Mt CO₂-eq additional storage (+153% over business as usual).

3. High-value utilization of by-products and residues shows the greatest single potential, with up to 206 Mt CO₂-eq additional storage (+178%).

4. Extending product lifetimes in buildings can add up to 67 Mt CO₂-eq by 2050 (+62%).

5. Reusing demolition wood in applications with a long life span can yield up to 67 Mt CO₂-eq of additional carbon storage, depending on uptake (+74%).

Combined, these measures could redirect a significant fraction of the >270 Mt CO₂-eq currently lost annually into durable carbon stores, unlocking systemic climate benefits.

To be implemented, this vision needs to be supported by strong policies. Specifically, current subsidies for bioenergy actively disincentivize cascading and long-term wood uses, by rewarding combustion of wood over reuse. Reforms should phase out these incentives and redirect support toward material applications with long life span, such as mass timber, panels, and insulation products. Public procurement, design standards, and quotas can further stimulate demand. In addition, large-scale investments in engineered wood processing capacity are also essential: for example, Germany alone uses >30 million m³ of wood annually in timber applications with a short life span, yet the current total production capacity of its panel industry is only 2–2.5 million m³ wood per year. This represents a bottleneck for redirecting larger shares of wood currently used for short-lived uses to, for example, panels production.

At the forest level, extending rotation lengths and diversifying species can improve timber supply while maintaining ecological resilience. With 74% of roundwood produced in Central and Northern Europe, but much of it directed to pulp and fuel, management changes could significantly shift outcomes. Importantly, climate risks such as declining forest productivity and potential future shifts in forest species must be integrated into long-term planning.

Overall, this study demonstrates that cascading wood use by prioritizing high-quality applications and circular wood reuse can increase Europe’s long-term wood-based carbon storage by hundreds of Mt CO₂-eq by 2050. With tailored regional approaches, aligned policy reforms, and targeted economic investments, wood can effectively become a cornerstone of Europe’s circular bioeconomy and climate neutrality pathway.