Beams unlock large carbon savings in reinforced concrete structures

Reinforced concrete structures significantly contribute to buildings’ embodied carbon, with floor design optimisation being crucial for material efficiency and structural decarbonisation. This study evaluates the embodied carbon, material use, cost, and labour intensity of seven cast-in-place reinforced concrete floor systems for a hypothetical four-story building in Brazil, considering four different column spans.

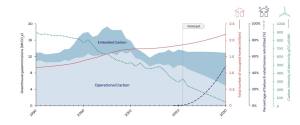

The primary difference among the floor systems is the number of beams used. Results show a 3.4-fold variation in the embodied carbon intensity among the 28 alternatives, ranging from 48 to 167 kg CO2/m2. Beam-supported floors have lower material intensity and embodied carbon, while flat slabs perform worse, especially for larger spans due to post-tensioning requirements. Despite higher formwork complexity, floor systems with more beams remain cost-competitive due to material savings, demonstrating that low-carbon and low-cost designs can coexist.

This study encourages structural designers to prioritise material-efficient solutions for decarbonising reinforced concrete structures. It shows that substantial savings can be achieved with current technology, offering practical ways to reduce buildings’ environmental impact while ensuring economic feasibility.