Natural fibres and waste materials boost concrete sustainability

News Detail

Year:

2022

Country:

Global

Source:

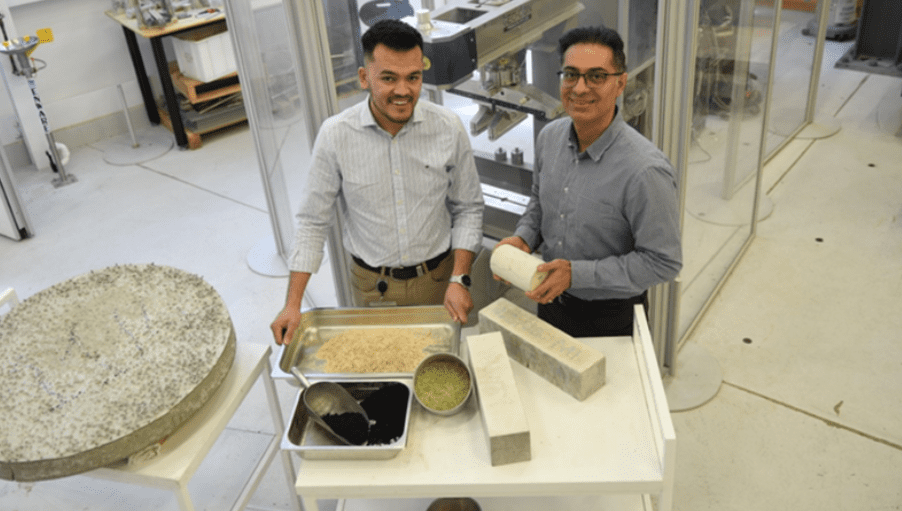

Institution of Mechanical EngineersNatural fibres and waste products can replace synthetic reinforcement materials to make a more sustainable type of concrete, researchers have said.

The team from Flinders University in Australia, working with experts in the US and Turkey, said that geopolymers reinforced with renewable natural fibres and made with industrial by-products and waste-based sands from lead smelting or glass-making can match the strength and durability of those containing natural sand, which consume more raw resources and generate more emissions.

Conventional concrete is the most widely used construction material, with 25bn tonnes used every year. It consumes about 30% of non-renewable natural resources, emitting about 8% of atmospheric greenhouse gases and comprising up to 50% of landfill.

The “promising findings” have significant potential for the use of natural fibres in the development of structural-grade construction materials, lead researcher Dr Aliakbar Gholampour said.

Geopolymers using waste glass sand have superior strength and lower water absorption than those containing natural river sand, tests found. Lead smelter slag-based geopolymers have lower drying shrinkage compared to geopolymers prepared with natural river sand.

Natural fibres such as ramie, sisal, hemp, coir, jute and bamboo were incorporated in experiments. The geopolymers containing 1% ramie, hemp and bamboo fibre, and 2% ramie fibre, exhibited higher compressive and tensile strength and a lower drying shrinkage than unreinforced geopolymers, the researchers said. 1% ramie fibre had the highest strength and lowest drying shrinkage.

The study adds to global efforts tackling the environmental impact of producing conventional building materials and landfill volumes, the team said.