HasleTre/

Oslotre AS

Project Details

Location(City/Country):

Bøkkerveien 2 Municipality Oslo / Norway

Tipology:

Offices

Year (Design/Construction):

- / 2023

Area (Net/Gross):

- / 2655 m2

Operational Carbon emissions (B6) kgCO2e/m2/y:

-

Embodied Carbon emissions (A1-A3) kgCO2e/m2:

-- Efficient and rational structural design with an optimised structural grid.

- Timber construction helps to reduce the embodied carbon of the building.

- Designed for disassembly allows for the reuse of the different elements at the end of life of the building.

- Use of natural materials throughout the building, predominantly cork, wool and timber.

- The hygrothermal properties of the organic materials help to reduce the energy consumption and to enhance occupants well-being.

- A substantial proportion of reused and upcycled materials, and 60% of the furniture made of upcycled pieces, enhance the circularity approach of this building.

- Natural ventilation system, to allow the users to ventilate the rooms.

HasleTre, the recipient of Norway’s distinguished Wooden Building of the Year 2022 award, serves as a pioneering model of sustainable architecture, driven by the imperative to combat climate challenges and shape a resilient future. Rooted in environmental consciousness, adaptability, and innovation, HasleTre not only meets functional needs but also slashes greenhouse gas emissions by 60% and secures the coveted BREEAM NOR Excellent certification.

Nestled at the outskirts of Oslo’s central city, HasleTre spans 3000m² over five floors, including basement and roof terraces. The directive was to craft an ecologically conscious, versatile, and inventive commercial structure designed for disassembly and reuse.

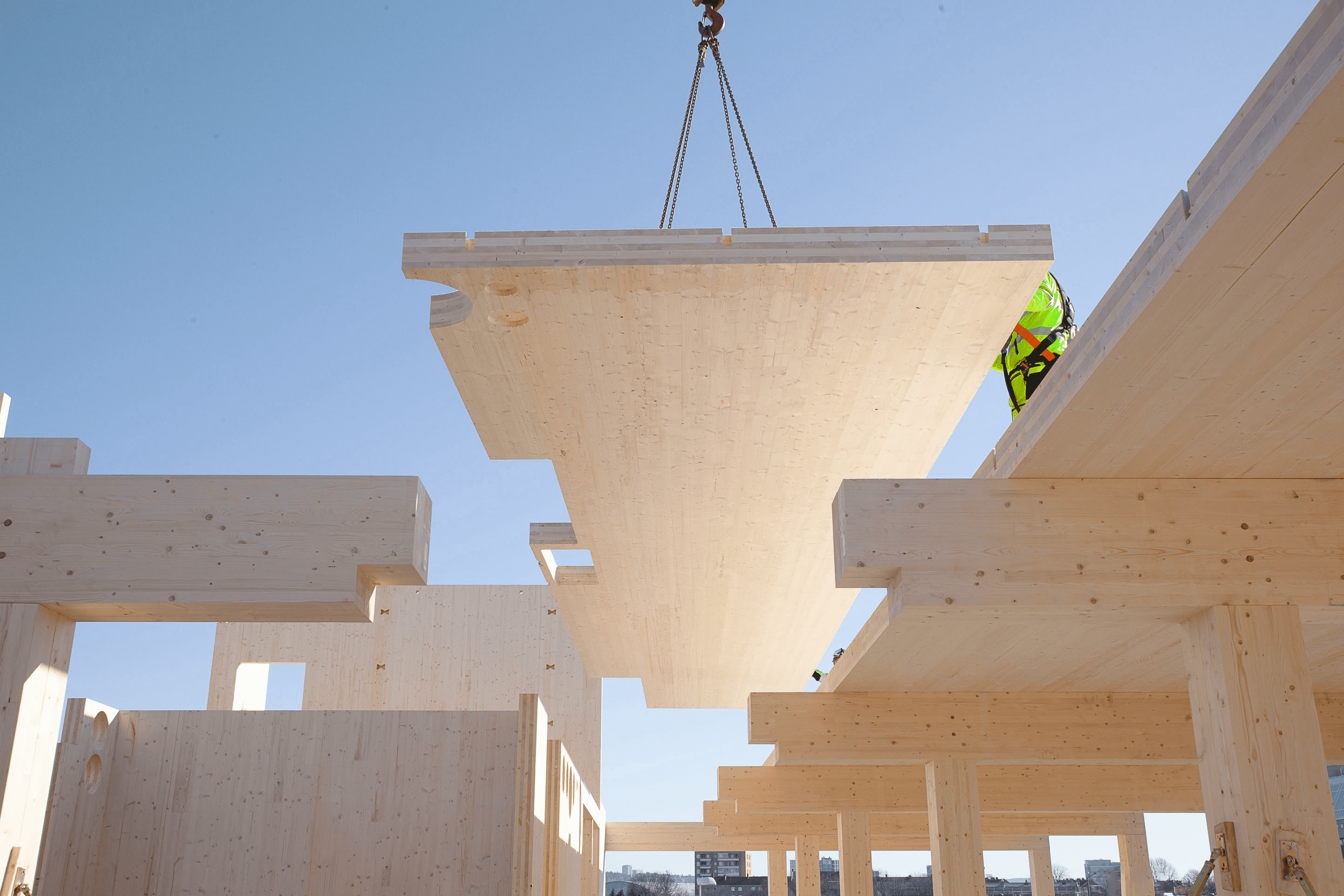

The structure boasts a mass timber framework, featuring a flexible 5×5 meter grid system accommodating varied plans like cell offices, open workspaces, meeting areas, and smaller rooms.

Yet, the journey wasn’t without challenges. Navigating the nexus of avant-garde construction techniques, materials, and regulatory compliance demanded meticulous equilibrium. Garnering widespread support for the disassembly and reuse concept necessitated comprehensive communication to elucidate its enduring benefits.

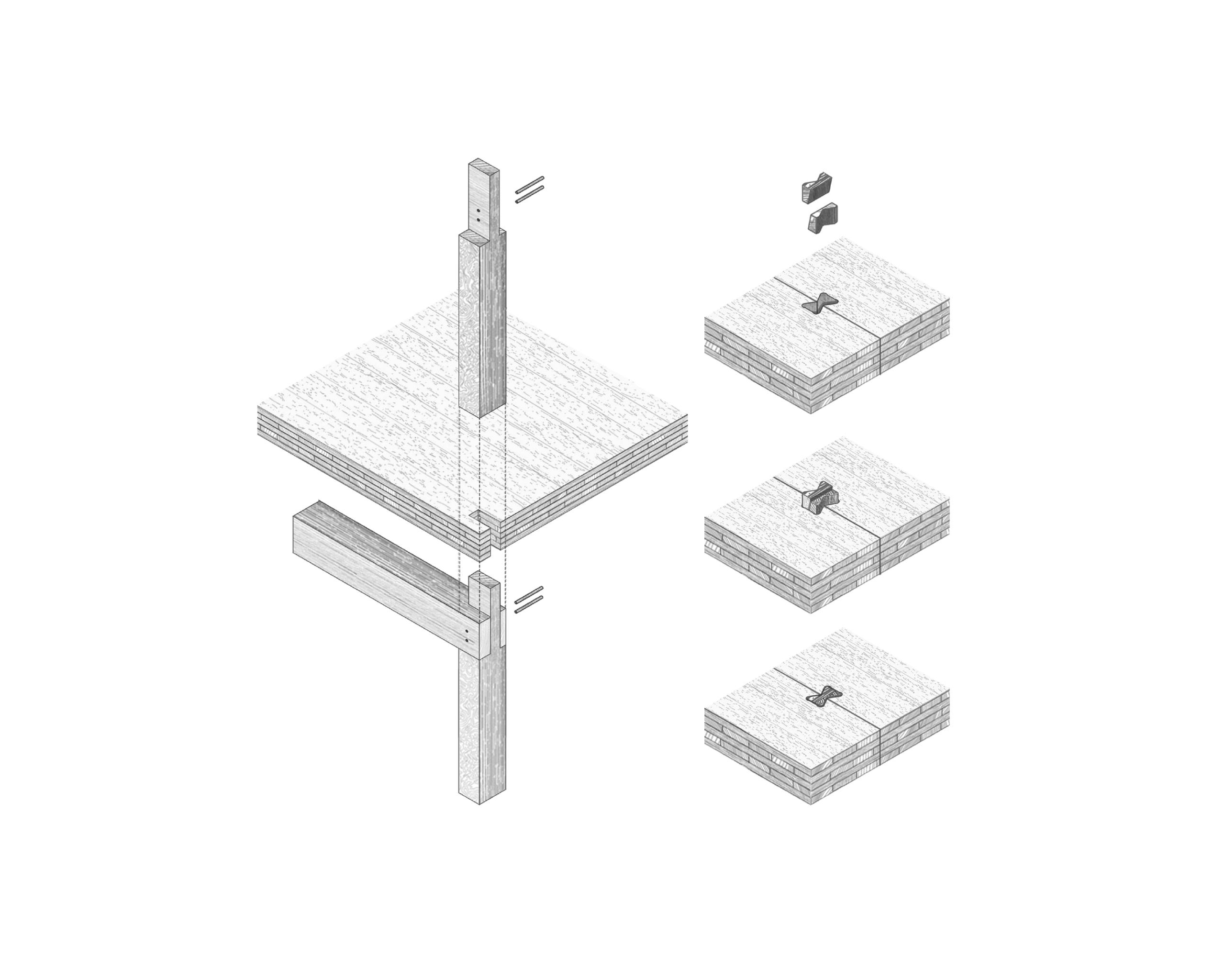

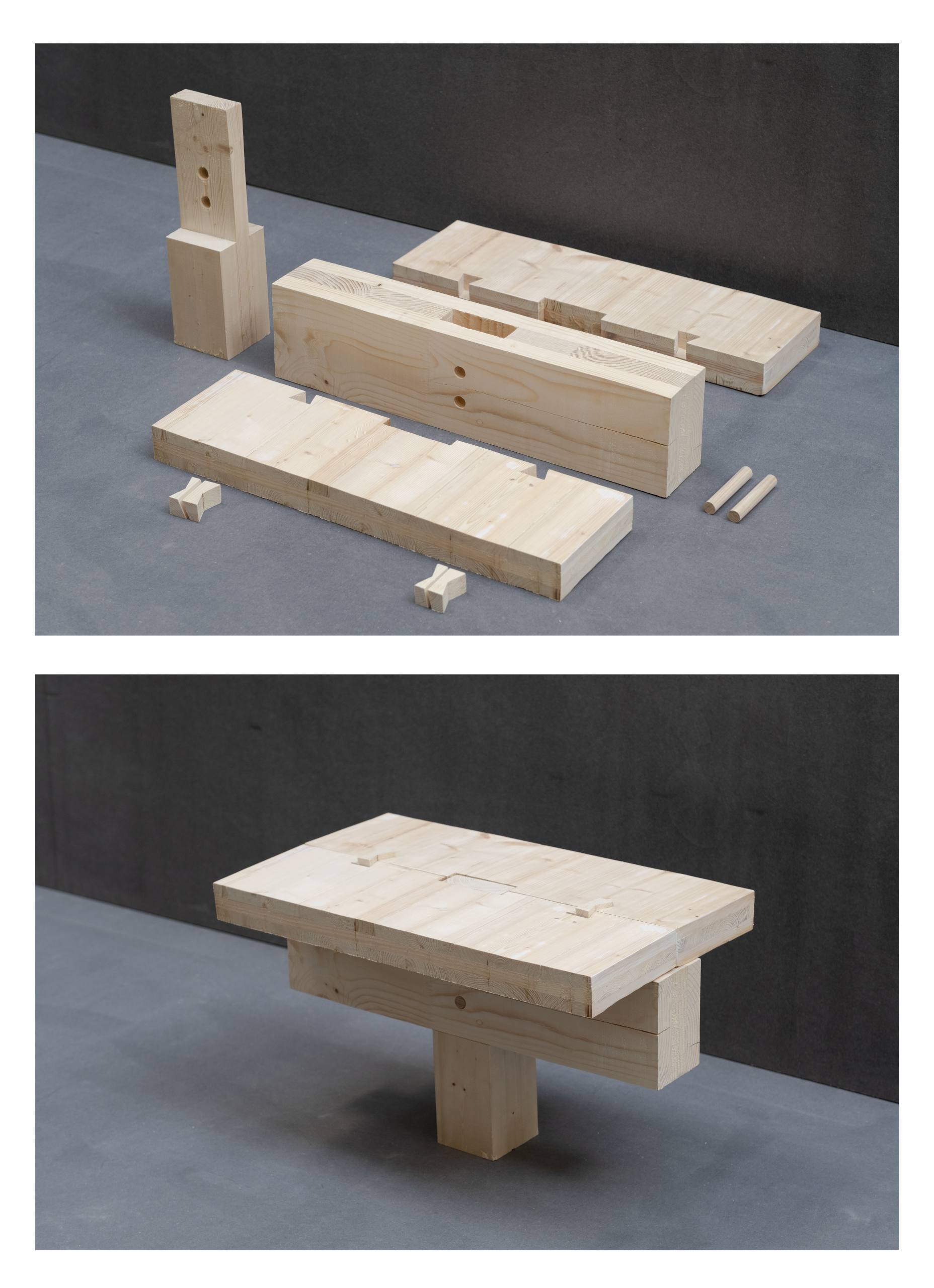

The commitment to disassembly materialized through meticulous component planning that facilitates both future assembly and disassembly. A primary and secondary framework designed around standard production formats and dimensions, coupled with minimal perforations through raw elements, curbs material waste and optimizes transport volumes. Ingenious timber-to-timber connections, such as glulam columns and beams joined with beech dowels, and CLT walls and slabs utilizing X-fix connectors, culminated in a steel-free construction system. This timber-centric approach curtailed steel use by over 80% compared to concrete alternatives, while adaptable technical solutions enhance longevity.

The interior predominantly features exposed wood, cork, and wool elements, with wooden nails used instead of screws for attachment. Harnessing the hygrothermal properties of these organic materials, the building aims to curtail energy consumption, enhance occupant well-being and focus, and mitigate sick leave instances.

The project integrates a substantial proportion of reused and upcycled materials, including ventilation aggregates, acoustic ceiling plates, and secondary room flooring. Moreover, 60% of the furniture constitutes upcycled pieces, while the remaining 40% incorporates biodegradable materials or industrial waste like ocean-harvested plastics.

Designed for durability and spatial-technical flexibility, HasleTre was remarkably erected in a record-setting nine-month span.

Additional Environmental Information

The steel use in the building is estimated to be reduced by 80% compared to the reference building. Multiconsult has calculated that HasleTre has 60% lower greenhouse gas emissions than the current industry standard (according to FutureBuilt Zero v01). 60% of all loose interior in the building is reused and upcycled. The building is designed for future reuse, and demountable materials can be traded on a secondary market. A significant amount of resources has been invested in the project to explore new solutions and methods. These have substantial transfer value to new projects.

- Estimated Energy Use Office: Estimated net energy demand 111 kWh/sqm gross floor area (106 kWh/sqm net floor area), estimated delivered energy 106 kWh/sqm gross floor area (101 kWh/sqm net floor area)

- Estimated Energy Use Retail/Outward-facing Area: Estimated net energy demand 146 kWh/sqm gross floor area (135 kWh/sqm net floor area), estimated delivered energy 145 kWh/sqm gross floor area (135 kWh/sqm net floor area)

- Area-weighted Average Estimated Energy Use Office and Retail/Outward-facing: Estimated net energy demand 114 kWh/sqm gross floor area (108 kWh/sqm net floor area), estimated delivered energy 109 kWh/sqm gross floor area (104 kWh/sqm net floor area)

- Net Floor Area per Employee 11 sqm Average U-value (W/sqmK)

- Exterior Walls: 0.22 W/m²K;

- Roof: 0.12 W/m²K;

- Floor: 0.12 W/m²K;

- Windows/Doors and Glazing: 0.73 W/m²K;

- Normalized Thermal Bridge Value: 0.03 W/m²K

Energy Sources District Heating and Electricity Ventilation Mechanical ventilation, but with some operable windows to allow users to ventilate.

- Material Usage The building is constructed with extensive use of wood in both structure, insulation, interior, and exterior.

- Extensive use of wood was a deliberate environmental choice from the conceptualization of the building.

- Contract Form Design-Build.

- Environmental Classification Breeam NOR Excellent.

- Client: Höegh Eiendom

- Contractor: Seltor AS

- Architect: Oslotre AS

- Team Members: Jørgen Tycho, Architect MNAL; Moritz Groba, Dipl. Ing. Architektur; Salas Montes Mañas, Civil Architect; Kristine Karklina, M.Arch; Katrin Wilde-Sampaio, Dipl. Ing. Architektur; Jon Danielsen Aar- hus, Civil Architect MNAL; Olivia Gragnon, CAD Engineer

- Interior Architect Fixed Furniture (Client side): I-d. Interiørarkitektur & Design as, Silje Brænde, Int. Ark. MA / MNIL and Are Fredrik Berg, Furniture Designer MA / MNIL;

- Loose Furniture (Tenant side): Romlaboratori- et AS, Kjersti Hoel Johnson, Interior Architect MNIL and Malin Skjelland Eriksen, Interior Architect MNIL

- Landscape Architect: Grindaker AS, Ingrid Klingberg, Landscape Architect MNLA and Denise Ines Peters, Landscape Architect MNLA

- Consultants Timber Engineering: Oslotre AS & NyStruktur AS

- Concrete Engineering: Norconsult AS

- Structural Engineering: Sweco AS

- HVAC Engineering: Rambøl AS

- Electrical Engineering: Ekom AS

- Plumbing Engineering: Engenius AS

- Fire Safety Engineering: Multiconsult AS

- Acoustic Engineering: Multiconsult AS

- Fire Engineering: F.M.Haaland As

- Breeam Certification: Multiconsult AS

- Cross-laminated Timber and Glulam Supply: Splitkon AS

- Photography: Dmitry Tkachenko, Einar Aslaksen