MEP Embodied Carbon: The elephant in the room, roof and basement…

News Detail

Year:

2022

Source:

2050 Materials

Embodied carbon targets and benchmarks give the sector good “rules of thumb” around the embodied carbon we should be targeting when designing a new building, or retrofitting. These benchmarks focus largely on architectural building materials like cement, steel, masonry and building interiors.

Are we missing something…?

Anyone who has done whole life-cycle carbon assessments is in on a little secret: we don’t really know (in detail) how much of the embodied carbon comes from mechanical, electrical, and plumbing (MEP) systems in the buildings. Most LCA specialists of sustainability consultants will increase their material-based embodied carbon emissions by a factor (10–30%) to include an estimate of MEP emissions.

However new research is now showing that MEP systems in high-rise office buildings can (frighteningly) contribute up to as much carbon as to that of the building’s structure and envelope combined

You read it right, MEP systems can add an 80%–100% of carbon to a building’s embodied carbon.

Out of site, out of benchmark?

The architect’s checklist to reduce MEP emissions (read on for more detail)

- Give passive design top priority.

- Adopt the “less is more” guiding principle.

- Use circular reasoning.

- Start early with life cycle assessments.

- Request EPDs from manufacturers.

- Keep in mind operational carbon along the route; whole life carbon thinking is key.

- Register on 2050 Materials to make this easier!

Recent research by Integral Group compared various residential space heating options available in the UK. A Variable Refrigerant Flow (VRF) split system that uses refrigerant for heating and/or cooling has embodied carbon emissions of roughly 800 kgCO2e/m2 during a 60-year period, which is equivalent to one-third of the operating energy use of a typical home during that time.

Up until now, the MEP equipment that makes it possible for our buildings to function efficiently hasn’t been taken into account by the industry. That certainly needs to change.

Source: https://www.canadianarchitect.com/hiding-in-plain-sight-embodied-carbon-mep-systems/

Frequent Replacement, All Metal, and Heavy Mass: A Recipe for High Embodied Carbon

The main reason MEP has high embodied carbon are the materials used to make the systems:

- Aluminum for motors and heat exchangers

- Copper for internal pipework

- Rare earth metals for electric batteries and solar PVs

- Steel for enclosures, support rails, and ductwork

- Cast iron for pipework

- Combination of other metals for boilers and chillers

Currently, to build new equipment, virgin metals must be mined, cleaned, and processed — a highly energy-intensive endeavour — due to the limited recyclability of the majority of these equipment types.

Furthermore, as the majority of the world’s mining occurs in a small number of nations, these metals must be transported over great distances to the factories where the finished goods are made. In the supply chain associated with the mining, extraction, and manufacturing processes that produce MEP systems, forced labor and ethical sourcing concerns are also major challenges.

“I think that in the future people will look back on 2018 as the year when climate reality hit. This is the moment when people start to realise that global warming is not a problem for future generations, but for us now.”

-Prof. Hans Joachim Schellnhuber, award-winning climatologist

The frequency of equipment replacement increases these environmental effects. Boilers and other HVAC equipment, including heat pumps, need to be replaced on average every 20 years. Every 3–7 years, the majority of lighting fixtures need to be updated. Throughout a building’s lifetime, this indicates recurring carbon impacts, much like building interiors.

CIBSE TM65: A methodology to calculate MEP emissions at scale

The Chartered Institute of Building Services Engineers (CIBSE) has developed CIBSE TM65, which includes addenda that demonstrate how to apply it internationally.

See more here: https://www.cibsejournal.com/technical/heart-of-the-matter-calculating-embodied-energy-using-tm65/

When there are no EPDs available, TM65 offers a reliable way to calculate the embodied carbon of MEP goods. The ultimate objective is to develop a knowledge base and useful rules of thumb that can help all engineers make the best choices early in the design process, which is when we can have the biggest influence.

Thankfully, today a large number of manufacturers of MEP systems are asking what they can do next to create EPDs for their goods. This is a significant victory for the sector and will speed up the process of making embodied carbon data more accessible and transparent for MEP systems.

MEP as a percentage of the total embodied carbon of an office building

In a previous study, it was discovered that, over the course of 30 years, the influence of MEP can account for 15% to 49% of the total embodied carbon in a commercial building (including PV systems and refrigerant leakage). It may however, go as high as 76% in the case of a refit.

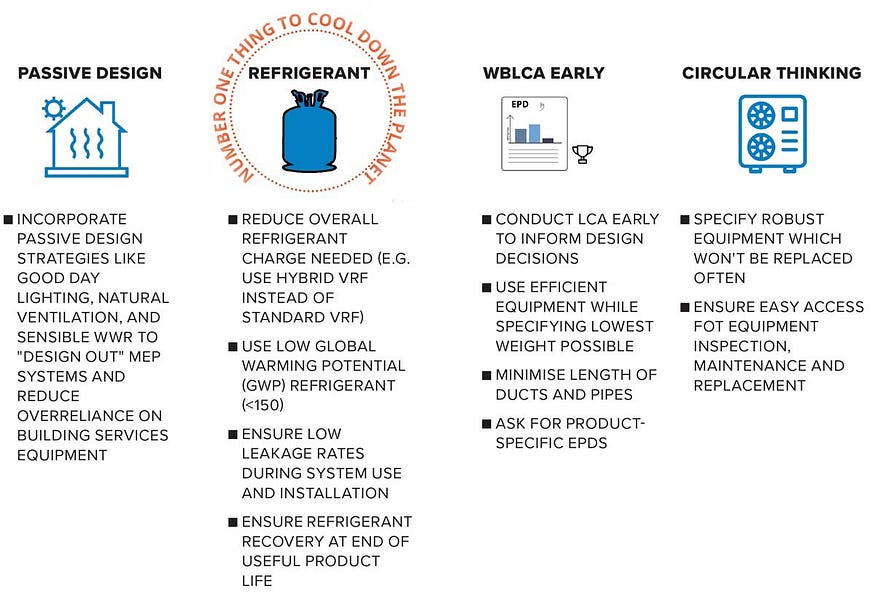

Key steps to mitigate the embodied carbon of MEP systems.

Important steps for architects

How can designers of MEP systems lessen their designs’ embedded carbon footprint? Here are the main tactics we suggest:

- Give passive design top priority.

To “design out” building services as much as possible, use a “fabric first” strategy and passive design principles including good daylighting, natural ventilation, and reasonable window-to-wall ratios. Changing the envelope performance from the standard (30 W/m2 load) to the Passive House design standard (10 W/m2) results in a 40% decrease in the embodied carbon of the mechanical equipment alone. - Adopt the “less is more” guiding principle.

Analyze the project schedule to identify areas where mechanical systems can be completely done away with. Work with the project engineers to specify lighter equipment when it is necessary to design them. Consider scale-related efficiencies as well. Having a single, higher-capacity piece of equipment has a lower embodied carbon impact than having several smaller pieces of equipment that together have the same total capacity. - Use circular reasoning.

Make sure that it is simple to check, maintain, and replace equipment. Indicate products and parts that can be quickly removed, disassembled, recycled, or reused after their useful lives are through. Give attention to producers who support Extended Product Responsibility and provide take-back programs. Additionally, look at leasing equipment rather than buying it altogether using Products as a Service (PaaS) models. The majority of MEP items use a lot of materials but have short lifespans. It’s crucial to strive for a longer use of those resources. - Start early with life cycle assessments.

As early in the design process as possible, begin creating and assessing LCA models alongside the engineer and LCA experts. To help you make better design decisions, iterate and improve the results. As operational and embodied carbon effects on MEP systems are intricately linked, consider them as a whole. - Request EPDs from manufacturers.

By mandating product-specific EPDs during bidding and procurement, you may promote data openness. Methodologies like CIBSE TM65 can be utilized to determine the embodied carbon impacts connected with MEP systems in the absence of EPDs. - Keep in mind operational carbon along the route; whole life carbon thinking is key.

It would be a mistake to put all of our attention on embodied carbon and ignore operational carbon. Instead, we need to design our buildings using a Whole Life Carbon strategy that takes operational and embodied carbon into account. To advance our understanding of this emerging field, we participate in numerous industry working groups, including ASHRAE and CIBSE. - Register on 2050 Materials to make this easier!

Register on 2050 Materials to make this easier

We built 2050 Materials to guide architects and designers design truly sustainable buildings.

The core of all work we do revolves around problems such as the MEP one, as well as solutions and actions to mitigate them. Join the free platform here, and reach out to us at [email protected] if you need additional support for a project.