Building the Future: Recycled Materials in Construction

News Detail

Source:

RevaluWith new regulations and more stringent limits for buildings’ carbon footprint, lower-carbon materials will likely see more widespread use in the industry. In one of our previous articles, Building the Future: Navigating Bio-Based Materials in Construction, we talked about bio-based solutions and how hemp and straw can help propel the green transition of the built environment. Today we will focus on materials that are either partially or entirely made from recycled sources.

Recyclability is pivotal when it comes to building materials, especially in the context of shifting the economy towards circularity. For a lot of materials used in construction, though, being easily recycled is still far from a reality. Plastic, in all its variations, is a prime example, but concrete — as well as steel or glass — are also notably challenging to repurpose.

Progress is rapidly being achieved for some of the least recyclable materials such as concrete (two examples can be found here and here), but in the meantime we should use materials that can be recycled as much as possible. Wood, textiles, aluminium, and some plastics all find a new use today, thanks to the innovations that some manufacturers are bringing.

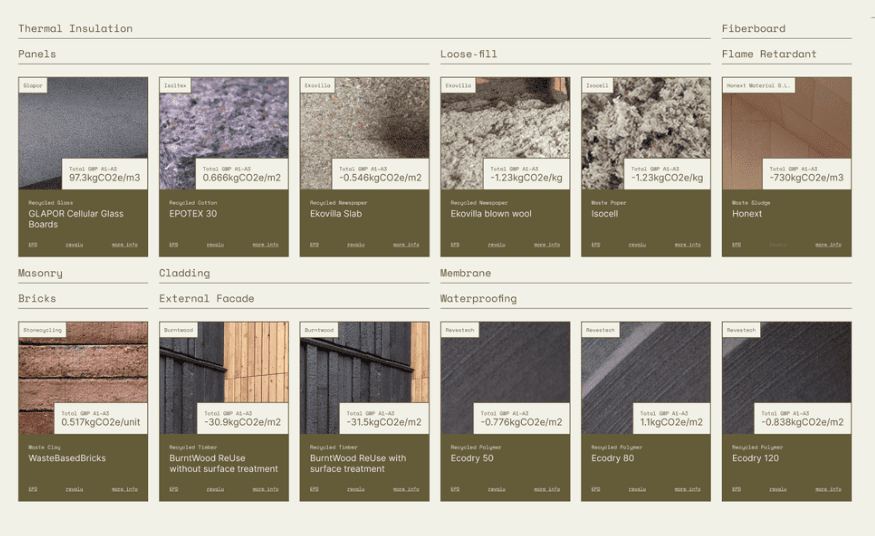

Here are some examples of solutions that make recycled materials an integral part of their design.

1. BurntWood

BurntWood specialises in facade elements made from recycled wood, contributing to CO2 storage in construction. Their process is developed from an ancient technique, known since the Viking era, which involves burning wood to remove sugars and lignin. The end-result creates a natural, durable, and water-resistant finish without the need for toxic chemicals. Crucially, BurntWood’s process allows for the utilisation of wood from various sources, including demolition sites, and is geared towards creating an endless supply of recycled wood.

Check out their EPDs here.

2. EcoUp

EcoUp’s Ekovilla insulation is made primarily from recycled wood fibre, such as old newspapers. Suitable for new constructions and renovations, Ekovilla stores CO2 in durable structures for decades and can be then recycled or reused for various purposes, including energy production or soil improvement. They offer different types of insulation, including slabs and blown wool, and focus on creating airtight, energy-efficient homes with their hermetic products. Additionally, EcoUp recycles mineral wool factory surplus into blown wool through their Eko-Expert division.

Check out their EPDs here.

3. Isoltex

Isoltex produces insulation from natural fabrics, notably recycled cotton from the textile industry. Their products offer better thermal and acoustic properties than mineral wool and are beneficial for both the environment and living spaces. Isoltex insulation doesn’t release VOCs (volatile organic compounds), is breathable, and contributes to energy savings. Additionally, it’s easy to handle and install, does not irritate the skin or respiratory tract, and is entirely recyclable.

Check out their EPDs here.

4. Revestech

Revestech is a European manufacturer focused on sustainable, innovative, and safe waterproofing systems. Their approach includes minimising waste, manufacturing toxin-free products, and designing fully recyclable products. Revestech offers waterproof membranes made from high-performance thermoplastic polyolefins, derived from recycled raw materials.

Check out their EPDs here.

5. Honext

Honext produces flame-retardant boards designed for circular construction. These boards are certified for their fire reaction and material health, not using any virgin materials, resins, or toxic additives in production. They also offer low emissions and are sound absorbent. Additionally, Honext boards are lightweight, flexible, breathable, and regulate indoor humidity. At the end of their lifecycle, they can be recycled, completing the circular design process.

6. StoneCycling

StoneCycling manufactures WasteBasedBricks®, made from at least 60% waste material. Their production is CO2 compensated and compliant with industry standards, suitable for both interiors and exteriors. They focus on upcycling waste into high-quality, aesthetic structures, offering custom-made services for unique project needs. StoneCycling also provides an Environmental Product Declaration (EPD) for their products, reflecting their commitment to transparency.

Check out their EPDs here.

7. Isocell

Isocell focuses on cellulose insulation products, primarily made from recycled newspapers.Their production process starts with treating the recycled paper to make it suitable for insulation purposes. This typically includes shredding, adding boric compounds for fire and pest resistance, and then fluffing it up to create a lightweight but effective insulation material. The end result is an insulation product that is not only made from almost entirely recycled material but is also recyclable at the end of its life-cycle. Isocell’s cellulose insulation has excellent thermal and acoustic properties and it’s fully certified for fire resistance.

Check out their EPDs here.

8. Recoma*

Recoma specialises in recycling composite packaging, such as beverage cartons, which are normally challenging to recycle. The process involves drying, sterilising, grinding, and pressing the materials under high temperature. The end result is boards made entirely from recycled material and which are also 100% recyclable. The recycled plastic in the cartons acts as a binder and waterproofing surface, while the aluminium content adds to the insulation value. This method of production doesn’t require deforestation, mining, additives, or water, and generates no waste, only requiring electricity.

*Disclaimer: Recoma’s EPD is expired and will be renewed in early 2024.

Though, while these solutions point out the benefits of reusing and recycling materials where possible, they also highlight that not all recycled materials are equally recycled. The percentages in recycled content can vary drastically from product to product, as well as the nature of the other ingredients such as binders or coatings.

This means that while working with recycled solutions can be a great way to lower the environmental footprint of a project, it also has to be done with care. Consulting the EPDs is a must for these kinds of products as they are the most reliable tool to get material data transparently.

More info